Summary:Oil filter element, oil separation core and oil separation core are all consumable parts of screw air compressor. They all have service life and must ...

Oil filter element, oil separation core and oil separation core are all consumable parts of

screw air compressor. They all have service life and must be replaced in time after expiration, otherwise blockage or rupture will occur, which will seriously affect the normal operation of the

air compressor. . The service life of "three filters" is generally 2000h, but due to the following reasons, the occurrence of blockage failures will be accelerated.

The oil filter element must be replaced in time when it expires, it is a vulnerable item. The reasons for the blockage of the early warning alarm are basically as follows: the quality of the oil filter itself has problems; the quality of the ambient air is poor and the dust is too large, which leads to the premature blockage of the oil filter, and the accumulation of air compressor oil. carbon phenomenon.

The air filter element is the air inlet of the air compressor, and the natural air enters the unit through the air filter and is compressed to form compressed air. The blockage of the air filter element is generally mainly caused by the surrounding environmental factors, such as the cement industry, ceramic industry, textile industry, furniture industry and other working environments, and the air filter element must be replaced frequently. In addition, the differential pressure transmitter fails to cause a fault alarm, and the differential pressure transmitter is damaged and replaced.

When the oil separator separates compressed air and oil, impurities will remain on the filter material, blocking the filter pores, resulting in excessive resistance, increasing the power consumption of the air compressor, which is not conducive to energy saving and emission reduction. There are volatile gases in the surrounding environment of the air compressor; the high temperature of the machine accelerates the oxidation of the

air compressor oil. Once these gases enter the air compressor, they will chemically react with the oil, resulting in carbon deposits and sludge. Part of the impurities entering the oil circulation system will be intercepted by the oil filter, and the other part of the impurities will rise to the oil with the oil and gas mixture. When the gas passes through the oil, these impurities will stay on the oil filter paper, blocking the filter holes, and the resistance of the oil will gradually increase. It is too large, so that the oil must be replaced in advance in a short period of time.

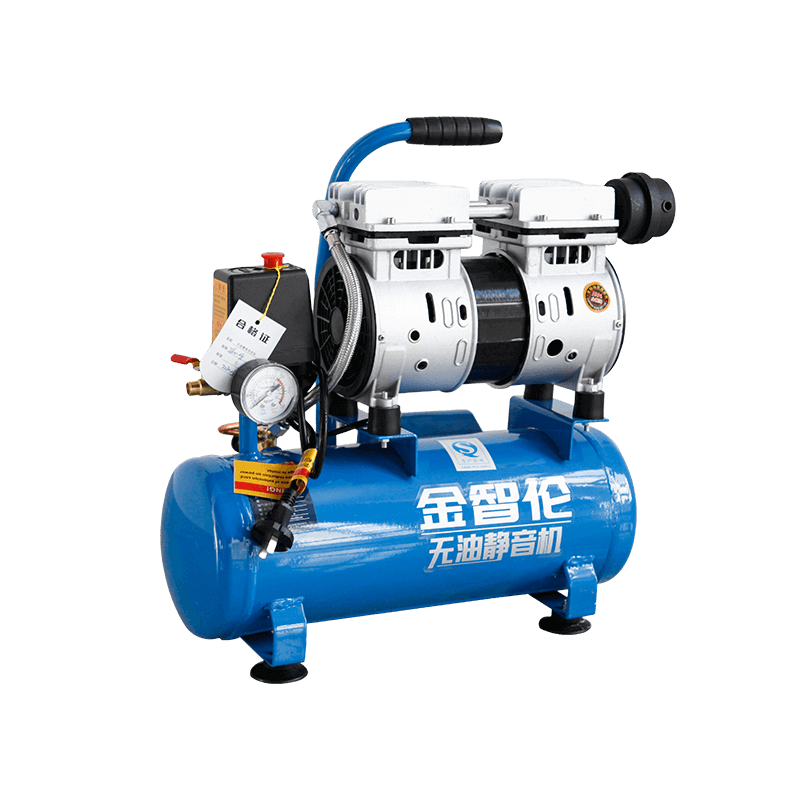

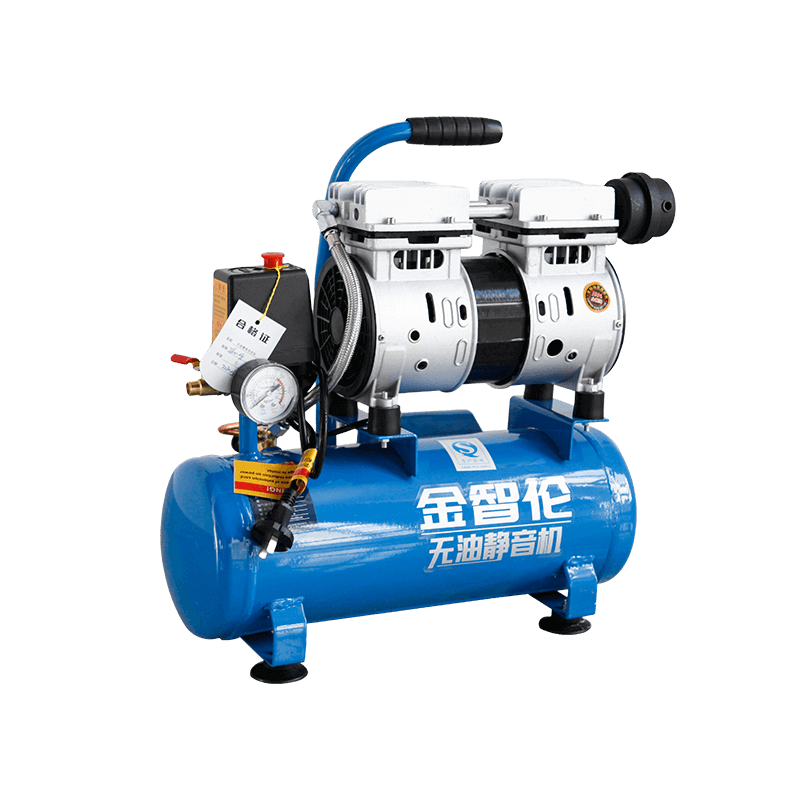

Location: China

Business Type:Manufacturer, Exporter

Brands:ZHEJIANG ZHILUN MECHANICAL & ELECTRICAL CO., LTD.

Terms of payment and delivery:L/C, T/T

Minimum order quantity:20 PCS

Price:Consultation

Packing details:Wooden case, Honeycomb case?

Delivery time:About 25 working days after receiving the deposit on our bank account

Payment method:FOB, CIF