Summary:In a complete pneumatic system, in addition to using an Belt-Driven air compressor to produce compressed air, post-processing equipment is also requir...

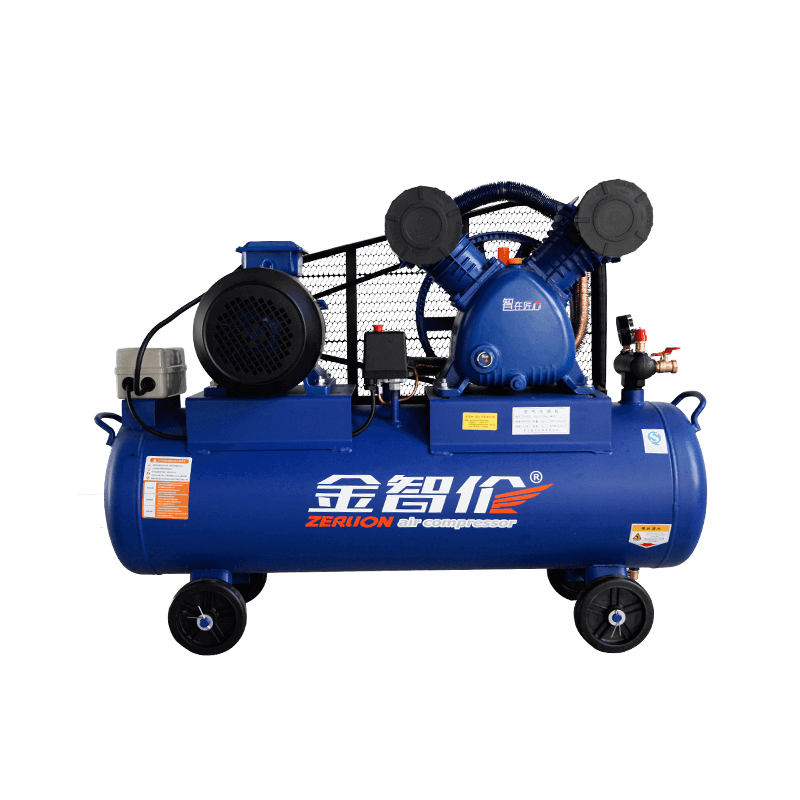

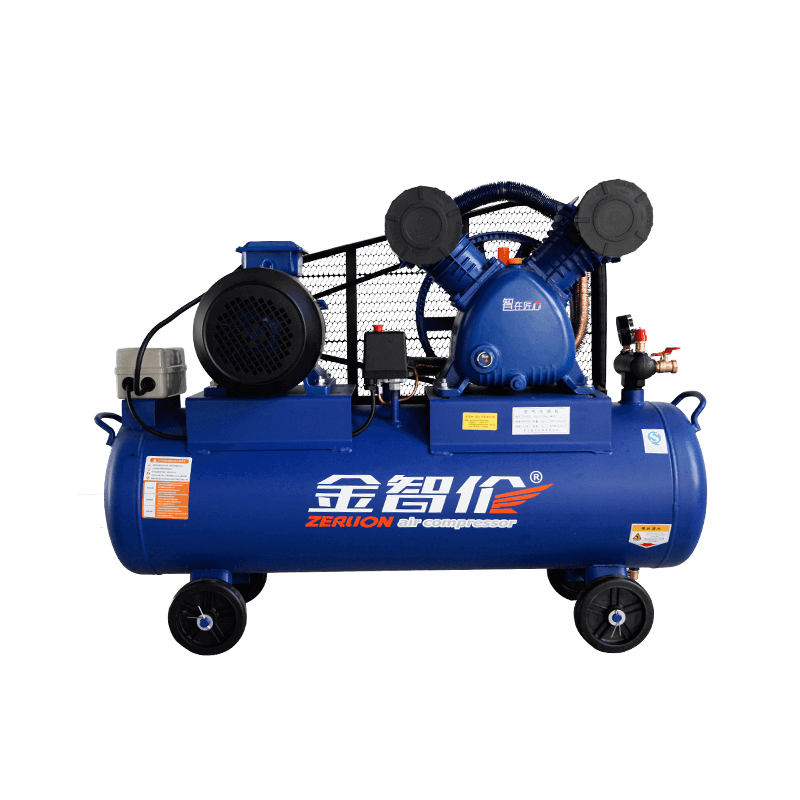

In a complete pneumatic system, in addition to using an

Belt-Driven air compressor to produce compressed air, post-processing equipment is also required to cool, dry and purify the compressed air. The post-processing equipment of the air compressor generally includes air storage tanks, dryers and filters, etc. Different models and operating conditions have different types of post-processing equipment. The specific methods are as follows:

1. The volume of the gas storage tank should be selected at about 1/6 of the compressor displacement, which can be appropriately enlarged according to the working conditions.

2. Precision filters can be divided into multiple levels according to the filtration precision. For example, the precision filters of air compressors are divided into four levels: C, T, A, and H, of which C is the primary filtration and H is the highest filtration precision. level. Under normal circumstances, the three-stage filter can meet the standards required by users, and special industries such as pharmaceuticals, electronics, etc., need to use four or five stages of filtration.

3. The processing capacity of the dryer should be consistent with the exhaust volume of the air compressor, and the filter before the dryer should be equipped with an automatic drain. When the air equipment requires the supply of compressed air with a dryness of -70°C (dew point), the heating regeneration type is generally used; if the supply of dry air around -40°C is required, the heatless regeneration type is generally used; When a win-win dry air of about -20°C is required, it is better to use a refrigerated compressed air drying device. The lower the pressure dew point, the higher the quality, which can be selected according to the gas requirements of the enterprise.

After the dryer is installed in the air storage tank, the function of the air storage tank is fully reflected, which plays the role of buffering, cooling and sewage discharge, and at the same time can reduce the load of the dryer, which is used for the uniform working condition of the system air supply. The dryer is installed before the air storage tank, and the system can provide a large peak adjustment capacity, which is mostly used in the working conditions with large fluctuations in air consumption.

We all know the importance of air compressor post-processing equipment, which can remove moisture, oil and impurities in compressed air, eliminate gas pulses, cool compressed air, etc., ensure the quality of

Oil free air compressor, and maintain great reliability of the pneumatic system , It is very necessary to choose the air compressor post-processing system correctly.

Location: China

Business Type:Manufacturer, Exporter

Brands:ZHEJIANG ZHILUN MECHANICAL & ELECTRICAL CO., LTD.

Terms of payment and delivery:L/C, T/T

Minimum order quantity:20 PCS

Price:Consultation

Packing details:Wooden case, Honeycomb case?

Delivery time:About 25 working days after receiving the deposit on our bank account

Payment method:FOB, CIF